There are many materials used in the construction process in the building industry, and different materials have different effects in the process of use. Deformation joints are one of them that are used very much in the construction of buildings.

So what are the main types of deformation joints?

Deformation joints can be divided into several types according to different setting positions: wall expansion joints, floor expansion joints and roof expansion joints. In the construction industry, expansion joints are used in general, especially in residential buildings and office buildings. Of course the location is different, the material is different and the usage is different. So when you buy, you need to choose according to the material, different material, different performance, different price. The same material, the thickness of the different, the price of the impact is also very big, the more difficult to install, the greater the risk, the higher the cost. Therefore, the selection should be made according to the user's requirements and the different environmental requirements of the building.

As we all know, because the building is in the middle of temperature change, in the day and night temperature cycle and the longer winter and summer days under the effect of rotation, the shape and size due to thermal expansion and contraction and change. When the length of the building exceeds a certain limit, it will be cracked due to large deformation. To prevent the onset of this cracking scene, the room along the length of the building bias at regular intervals reserved for cracks, the building will be disconnected. Such cracks are called deformation joints, which include expansion joints, settlement joints and anti-vibration joints. This requires the construction personnel to deal with the construction of expansion joints construction. In the choice of materials, in addition to considering its strength and stiffness of the reinforcement effect, should also consider its convenience for subsequent construction.

Generally speaking, the expansion joints are different from the settlement joints, which are required to disconnect all the above-ground components of the walls, floors and roofs of the building, and the roots are less affected by the temperature change and do not need to be disconnected. Its setting spacing is the allowable length of the building is based on the material used in the structure, the type of structure, construction methods, the construction of the geographic position and the situation is closely related. Its crack width is usually 20-30mm, while the settlement joints are cracks set up to prevent the uneven settlement of the foundation, additional stresses will occur in the structure, so that some thin parts of the building will have vertical misalignment cracking. It is required that all members from the foundation to the roof must be separated by joints, so that the construction on both sides of the settlement joints becomes a self-reliant unit, and each unit can settle freely in the vertical direction, without constraints. From the plane, the higher the structure part is, the more cracks are developed, and the closer to the fault, the stronger the crack development is.

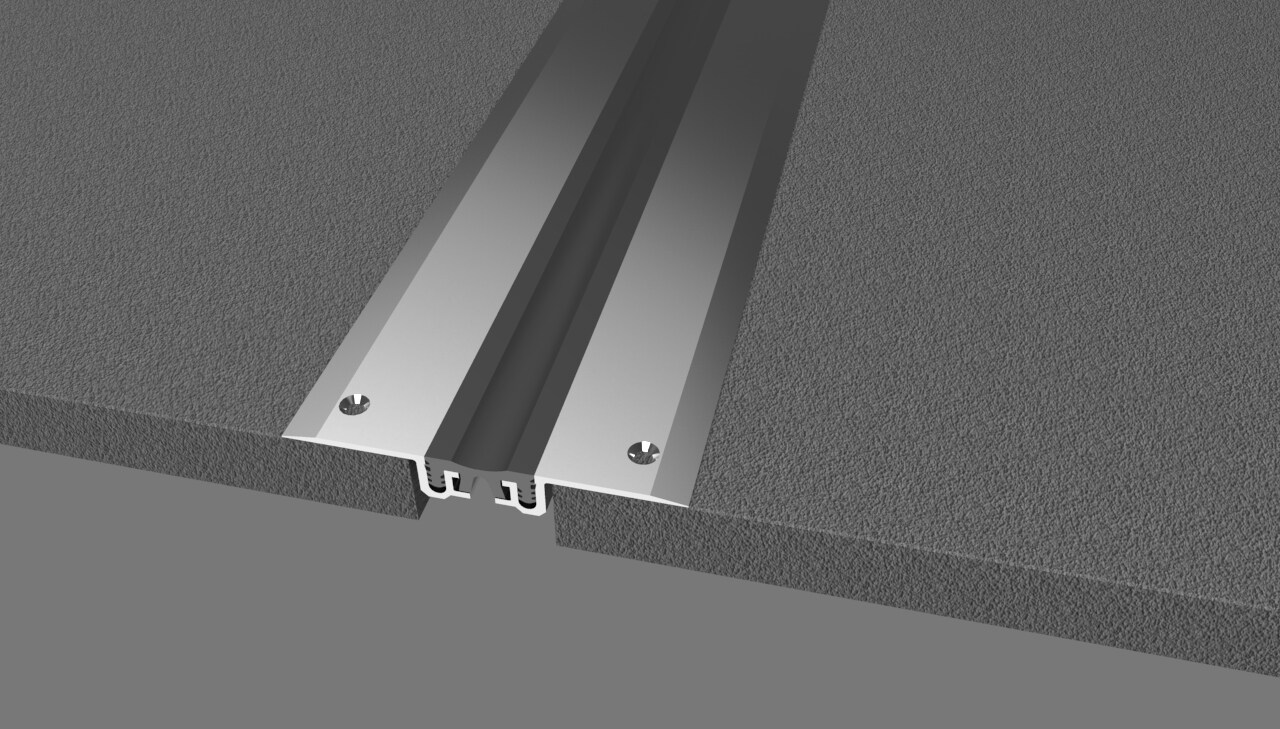

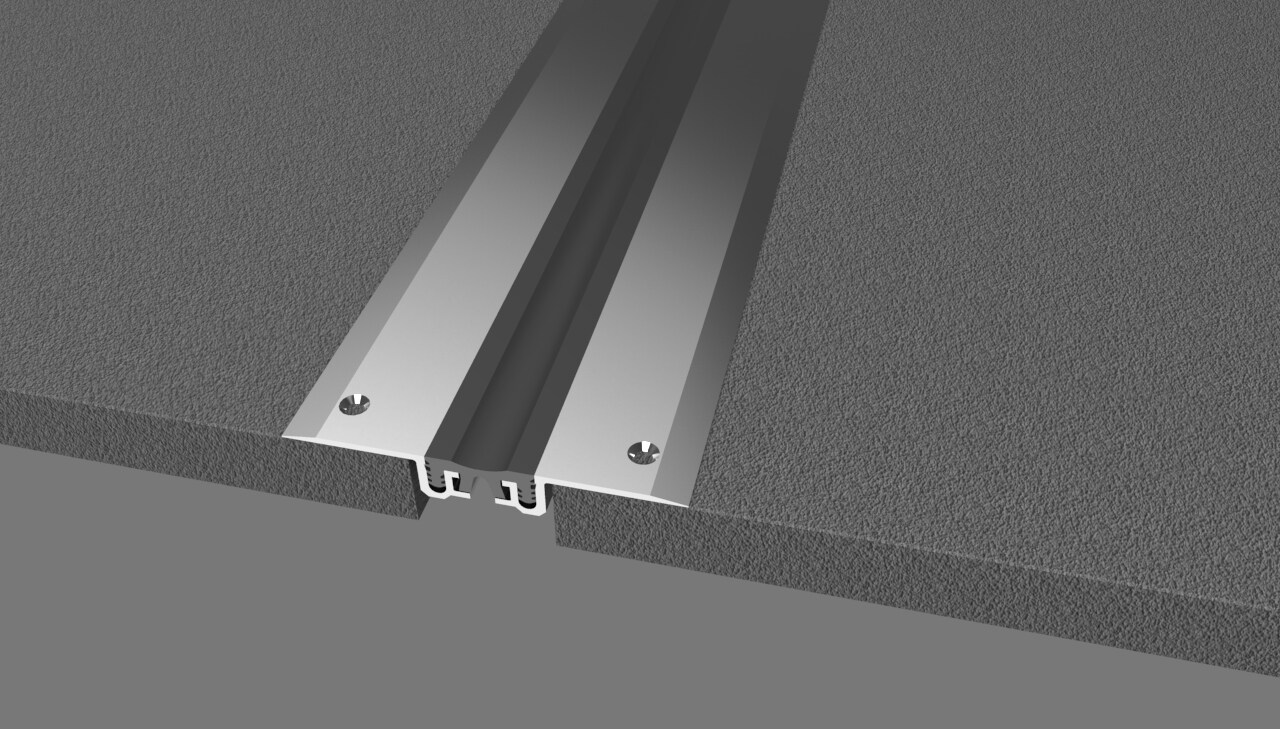

Our new deformation joints need to be used together with screws, and both sides need to be drilled and then fixed with screws. After it is fixed, it is also very strong. If there is a little deformation, even if it is just installed for two or three years, there will definitely be problems after a long time, and the roof is a place of high heat and humidity, there will be a hidden danger of water leakage. So before installation, you must do a good job of planning the installation, but also have enough safety awareness, all aspects of the work should be done, so as to reduce a lot of problems. When installing, be sure to check the model and the location of the installation, if it does not match, do not install it.

About Us:

Certificate:

Packing&Shipping:

By sea & by air, 25-30 days deliver time, stick protective film for each pcs.including stick lable. 20 pcs/ctn, 40 pcs/ctn, 60 pcs/ctn and 100 pcs/ctn all can.